Ferrite magnet

Short Description:

Ferrite Magnets Introduction Specification & Magnetic Properties Features Ferrite production process Flow Photos of Common Shapes like Ring, Disc, Arc, Block Introduction Ferrite magnets are permanent magnets , not rare earth magnets, it is mainly made from iron oxide and strontium carbonate by ceramic processing technology, also called ceramic magnets. Ferrite magnets are brittle, can be manufactured by die pressing and then sintering, can be made into various shapes and sizes. Its ...

Product Detail

Product Tags

Ferrite Magnets

- Introduction

- Specification & Magnetic Properties

- Features

- Ferrite production process Flow

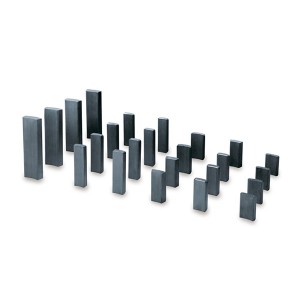

- Photos of Common Shapes like Ring, Disc, Arc, Block

Introduction

Ferrite magnets are permanent magnets , not rare earth magnets, it is mainly made from iron oxide and strontium carbonate by ceramic processing technology, also called ceramic magnets.

Ferrite magnets are brittle, can be manufactured by die pressing and then sintering, can be made into various shapes and sizes. Its normal operating temperature is between -40℃ and 250℃. Ceramic magnets are the most commonly used permanent magnet materials due to their low cost, easy to produce, excellent corrosion and demagnetization resistance properties. It can be produced either isotropic or anisotropic. C3, C5 & C8 magnets are anisotropic. If you need the strongest magnetic materials, we suggest sintered NdFeB magnets like N52.

Specification & Magnetic Properties

Type: Permanent Magnet

Material: Sintered Ferrite

Grade: Y30, Y30BH, Y33 etc(Download Magnetic Property Sheet of Sintered Ferrite Magnets)

Shape & Size & Tolerance: According to clients’ requirement, can custom special & complex shapes

Application: industrial, motors, speaker, air conditioning systems, crafts, daily life, cow, etc.

Features

Sintered Ferrite magnets are produced by adopting the method of powder metallurgy. They are low in remanence, small in magnetic permeability, bigger in Coercive force and strong in resistance to demagnetization, which are especially suitable used as the magnetic circuit structure of the dynamic working conditions. Ferrite material is hard and brittle, can be cut by silicon carbide tools. Isotropic ferrite permanent magnets are weak in magnetism but can be magnetized in different orientation.Anisotropic sintered ferrite magnets have strong magnetic performance, but only magnetized along the designated orientation.

Ferrite production process Flow